3D Stereo Video Borescope with 3D Modeling

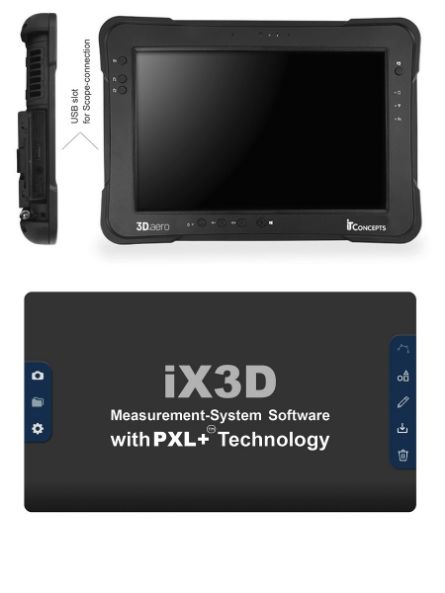

iX3D

3D Stereo Measurement Videscope

Flexibel Scope 3D Stereo Measurement System

Probe Diameter: 6mm, Length: 1.5m - 7.5m

3D Stereo Measurement Video Borescope with 3D Modeling

iX3D

Enhanced Borescopy with Stereo Vision Technology

iX3D is an advanced videoscope system designed for accurate and efficient point-to-point and three-dimensional surface inspections in hard-to-reach areas. This system offers various probes, each equipped with a stereo vision camera that generates 3D data for detailed inspection. The user-friendly interface is intuitive and straightforward measurement process is meticulously designed providing comprehensive control for the operator. The monitor unit can be positioned independently from the probe, allowing for easy data reading in diverse environments.

Despite its advanced technology and the complexity of inspections, the system has an almost zero learning curve for operators.

Customization options, including specific designs, additional functionalities, or integration into a desired system, can be implemented to meet customer requirements.

for Remote Visual Inspection

3D stereo measurement video borescopes represent a sophisticated advancement in remote visual inspection (RVI) technology, enabling precise three-dimensional assessment of intricate and inaccessible areas. By utilizing stereo vision techniques and a diverse array of RVI methodologies, these advanced instruments facilitate accurate measurements for comprehensive evaluation of internal components and surfaces. This detailed inspection capability also aids in more reliable detection of damages and defects, further enhancing the effectiveness of RVI applications in various industries.

Stereoscopic imaging, a prevalent 3D stereo measurement technique in advanced video borescopes for remote visual inspections (RVI), is grounded in the principle of parallax. Utilizing a dual-camera (image sensor) system with fixed separation distance, the technique captures distinct perspective images of the inspection area. By assessing the disparities between these images, the system calculates depth information, thereby generating a 3D representation of the inspected object's surface. In order to optimize the depth estimation process, sophisticated algorithms, such as global and local stereo matching techniques, are implemented. Moreover, contemporary systems might incorporate artificial intellect (AI), machine learning (ML) and computer vision (CV) technologies to bolster the accuracy of the stereo correspondence process.

Other 3D stereo measurement methods employed in RVI and specifically video borescopes include photogrammetry, structured light techniques, also known as phase-shift profilometry, and laser-assisted measurement (or laser line triangulation) with additional laser accessories. Photogrammetry involves capturing multiple images from different angles and using software algorithms to reconstruct a 3D model of the inspection area. Phase-shift profilometry projects a specific light pattern onto the surface under inspection, which is then captured by the borescope's camera. The distortion of the light pattern reveals information about the surface geometry, allowing the creation of a 3D model.

Laser-assisted measurement with optional laser accessories employs a laser line projected onto the inspection area, and the camera captures the reflected laser line to calculate the surface profile. Laser-assisted measurement does not offer 3D stereo measurement in the same way as true 3D stereo measurement techniques; however, it presents a straightforward and effective method for acquiring measurement data during RVI.

Compared to other stereo measurement techniques, stereoscopic imaging offers several advantages in the RVI domain:

- Precision: Stereoscopic imaging yields highly accurate measurements of distances, angles, and complex geometries in hard-to-reach areas, making it a valuable tool for various industries, including aerospace, automotive, oil and gas, and manufacturing.

- Robustness: Stereoscopic imaging is less susceptible to variations in lighting conditions, surface textures, and object reflectivity than some other methods, such as structured light techniques or laser-assisted measurements.

- Real-Time Processing: Stereoscopic imaging allows for real-time processing of 3D data, enabling operators to make informed decisions and take appropriate action during the inspection process.

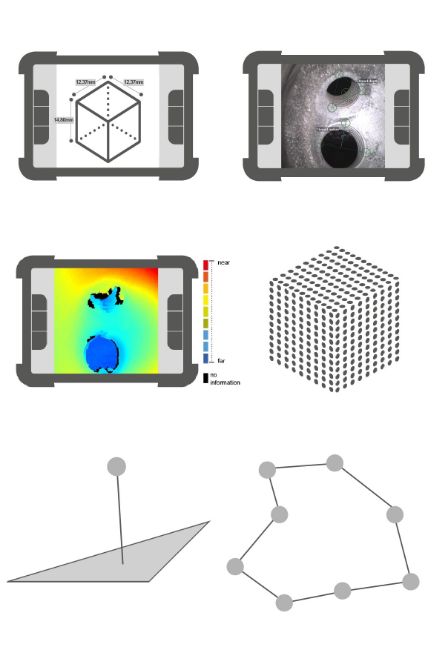

- Stereo Vision Technology: The integration of stereo vision cameras enables the generation of accurate 3D data by capturing two slightly different images of the inspection area. The system processes these images to create a depth map, providing a detailed three-dimensional representation of the inspected surface.

- High-Resolution Imaging: Advanced 3D stereo measurement video borescopes offer high-resolution imaging capabilities for enhanced detail and image quality. This feature is essential for accurate defect detection and reliable measurement results.

- Articulation Control: Precise articulation control enables the operator to navigate and position the probe tip accurately within complex and curved pathways, ensuring optimal inspection coverage.

- User-friendly Interface: Intuitive user interfaces and software applications facilitate easy operation, data analysis, and reporting.

- Customization Options: Customized solutions, including specific designs, additional functionalities, or integration into existing systems, can be implemented to meet customer requirements.

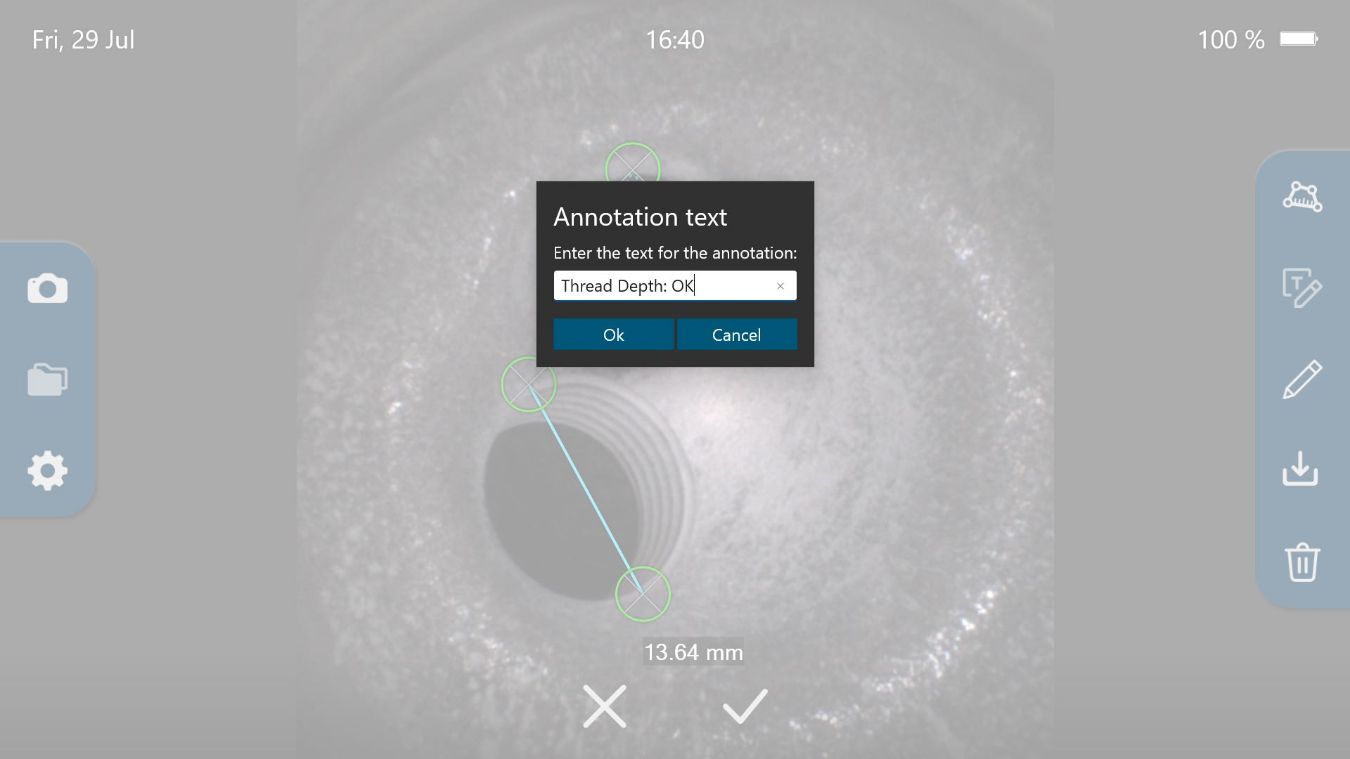

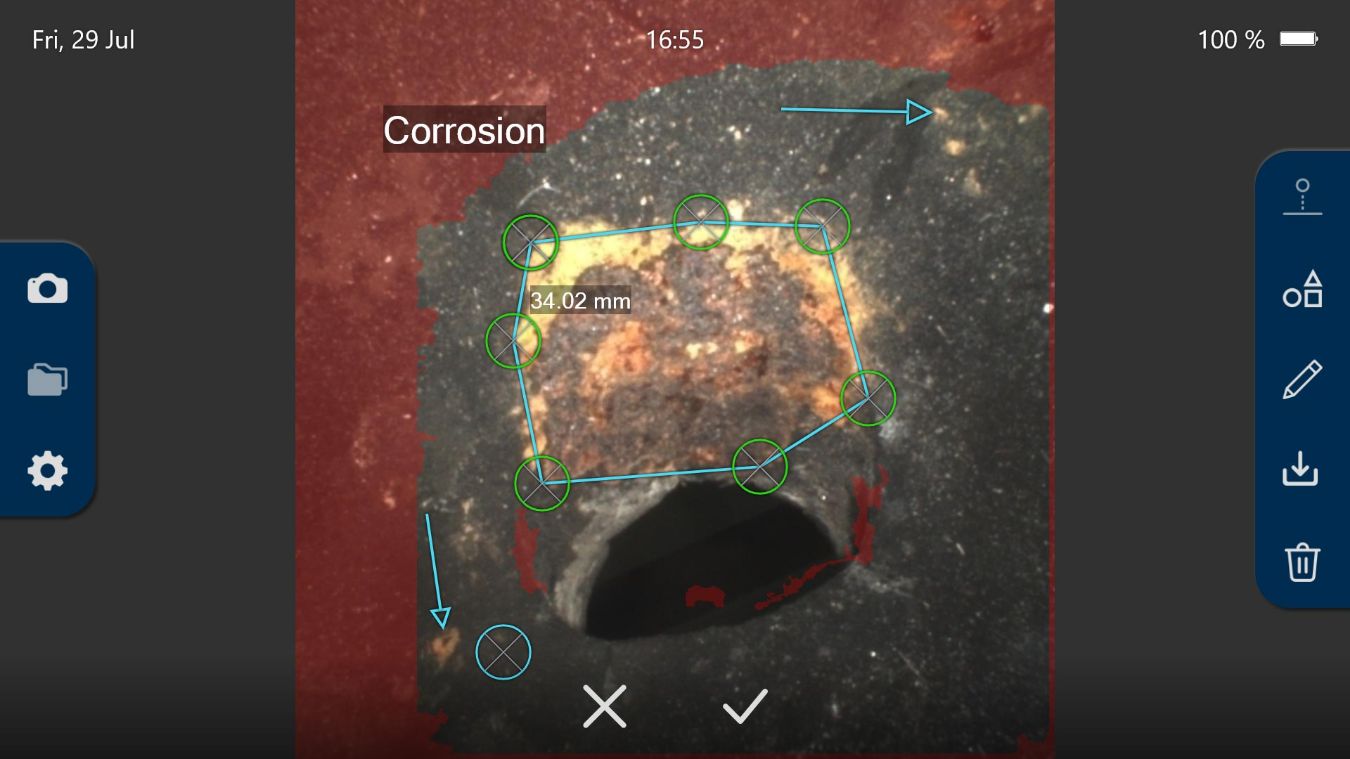

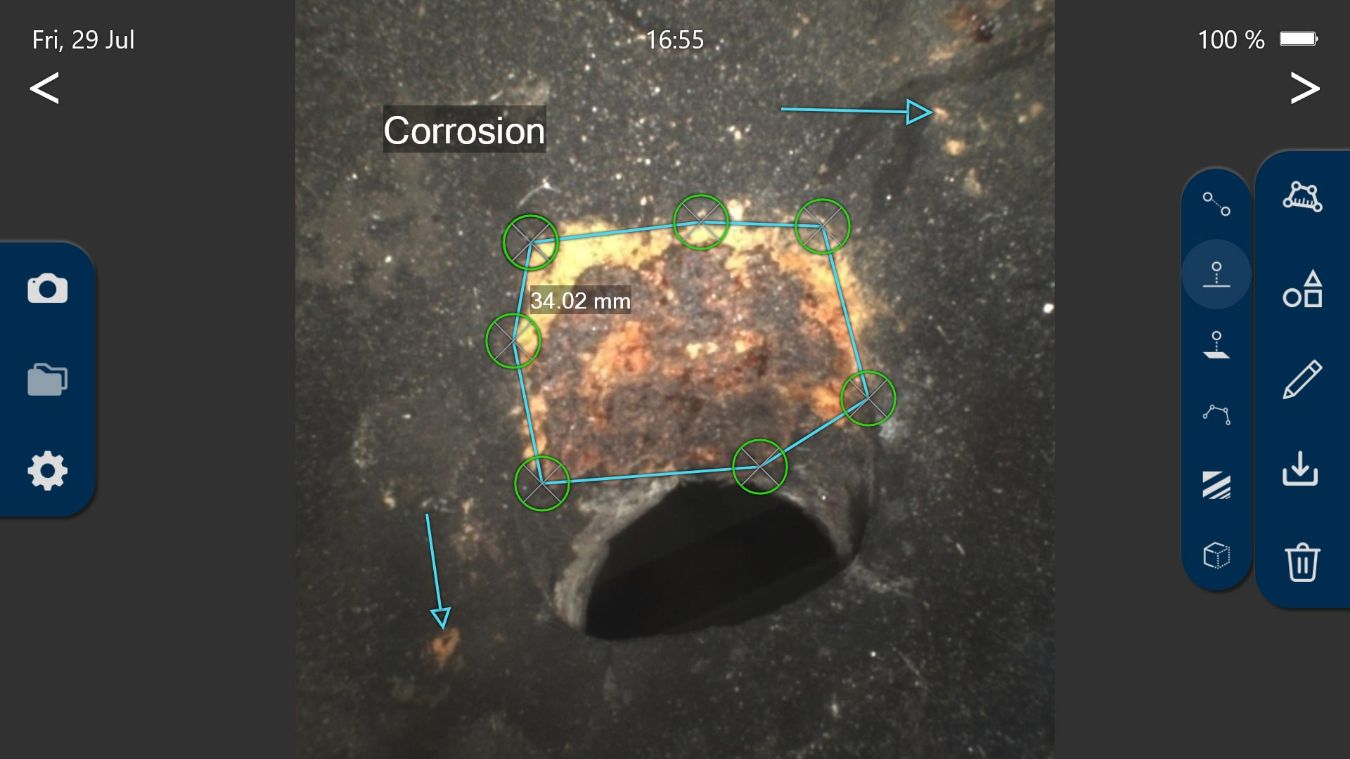

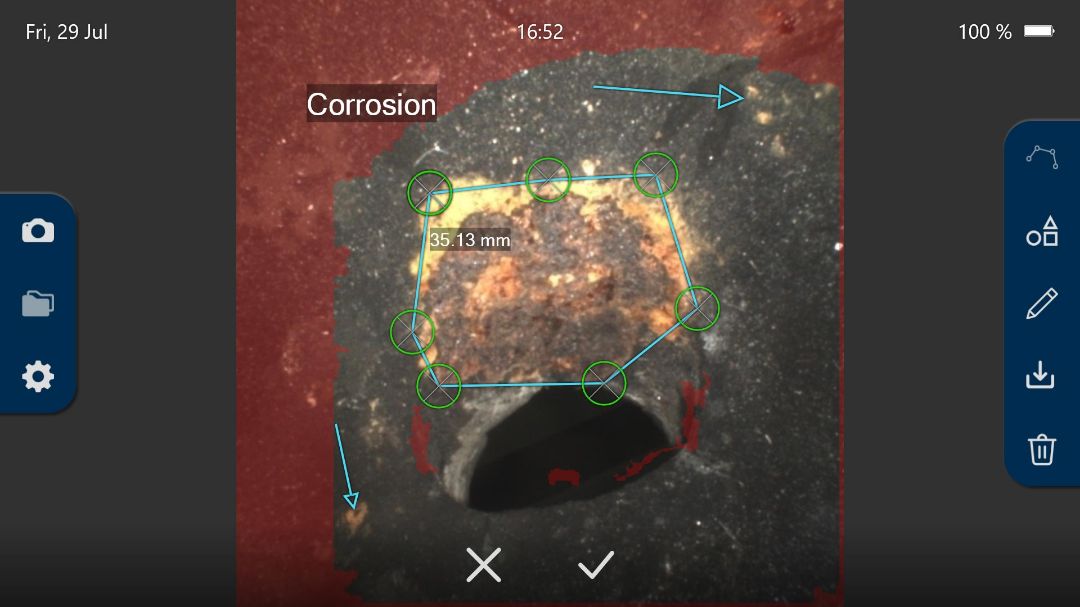

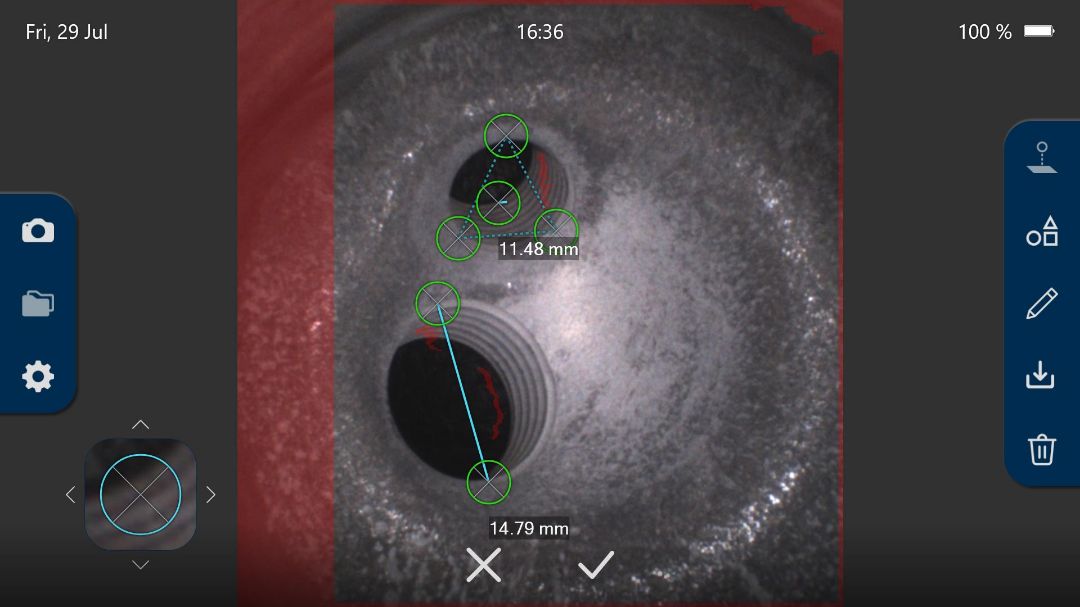

- Point-to-Point Measurement: This method measures the distance between two points on the inspected surface, providing accurate linear measurements for the evaluation of defects, wear, and other surface irregularities.

- Point-to-Line Measurement: By measuring the distance between a point and a reference line, this technique allows for the assessment of deviations from an expected linear path or the detection of surface undulations.

- Point-to-Plane Measurement: This method calculates the distance between a point and a reference plane, enabling the evaluation of surface flatness or concavity.

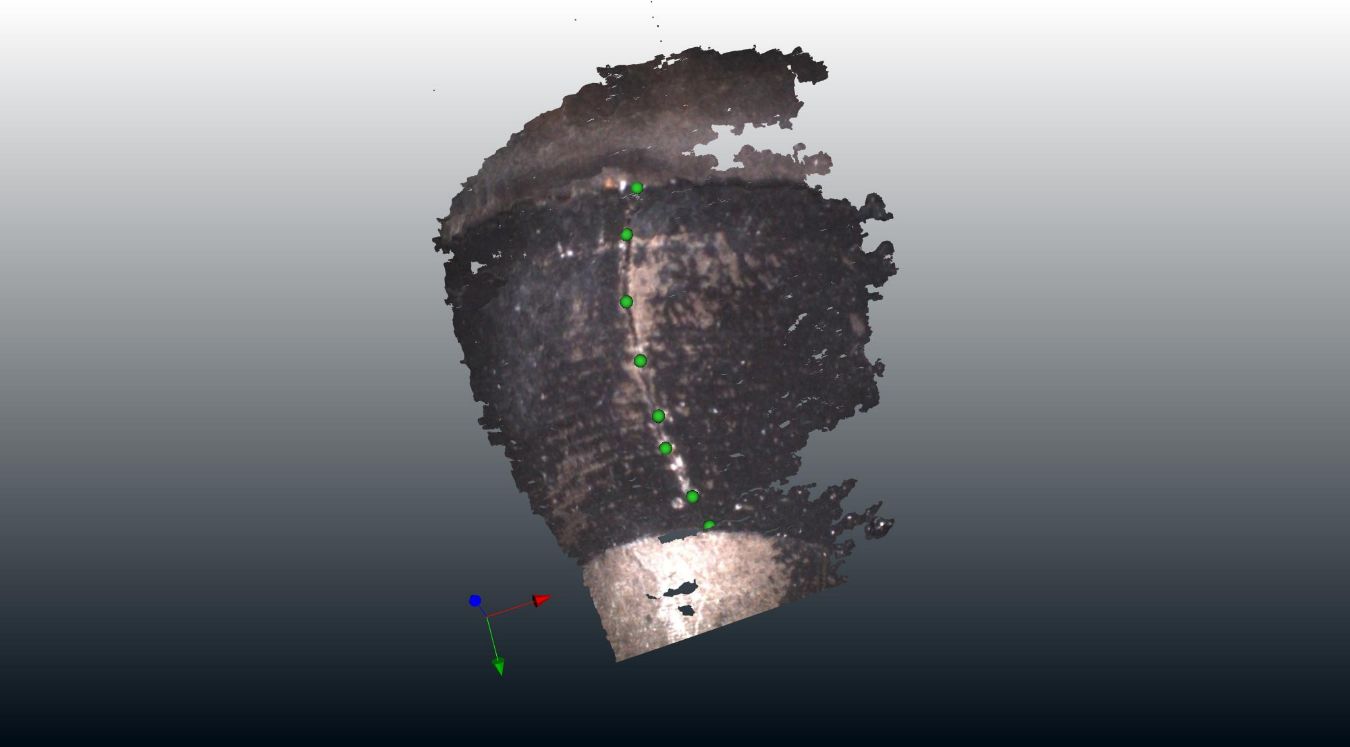

- Multi-point Line Measurement: By measuring multiple points along a line, this technique provides a comprehensive profile of the inspected surface, enabling the detection of trends or patterns in surface irregularities.

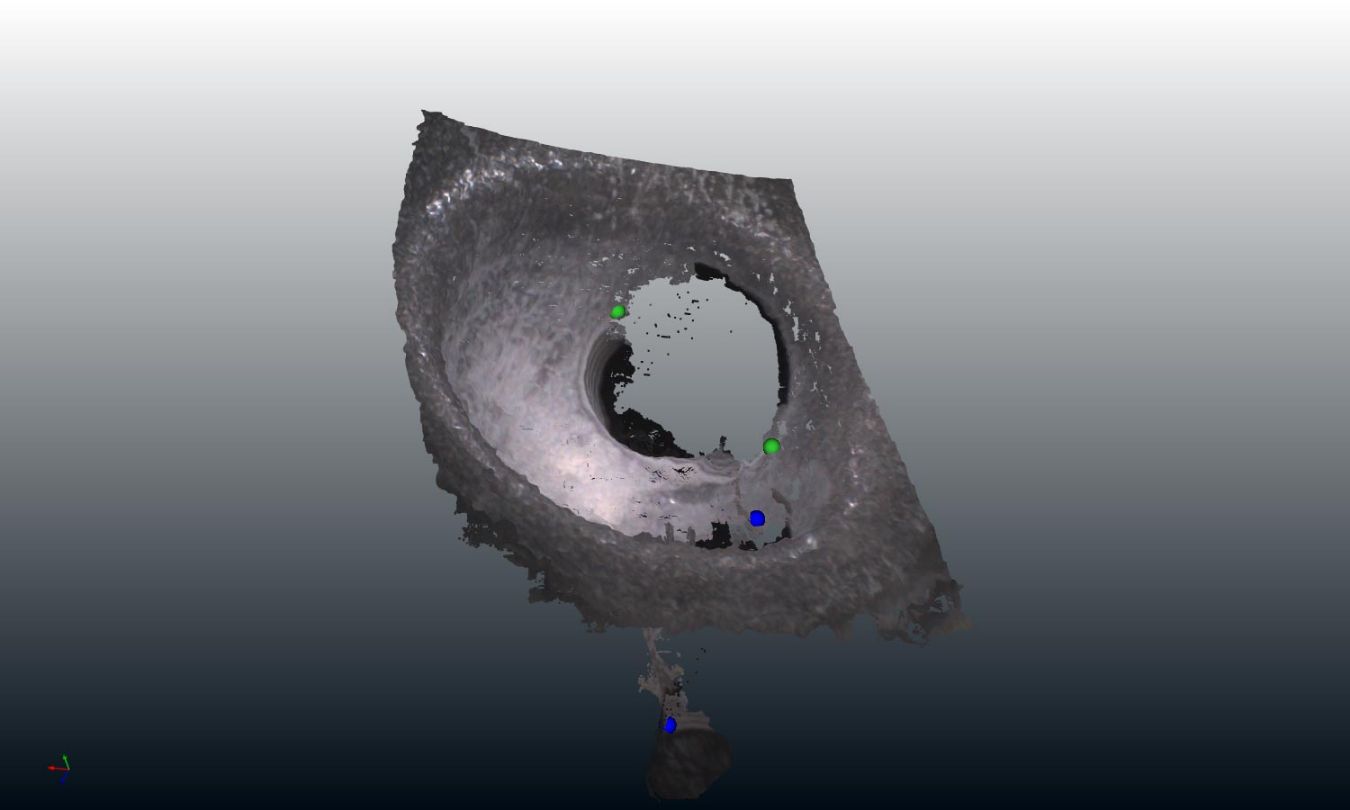

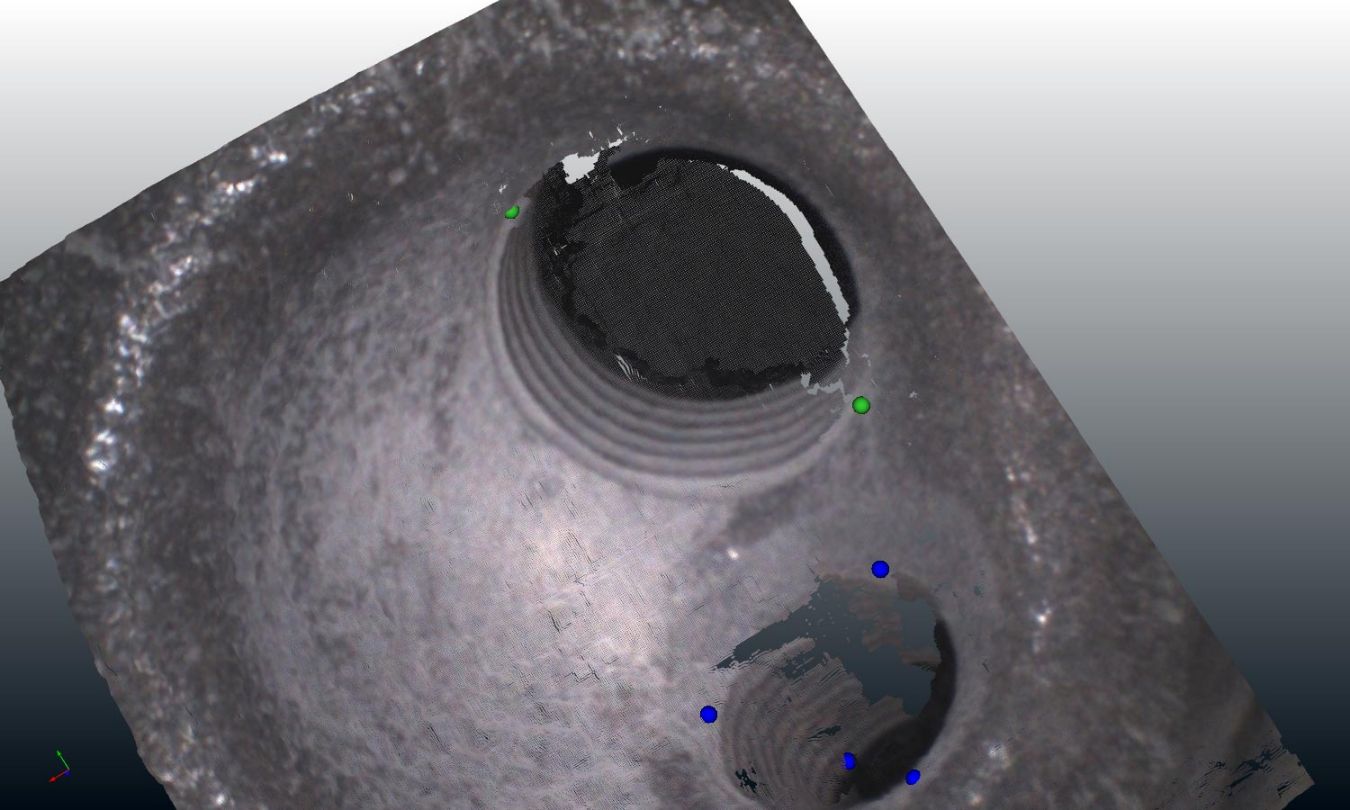

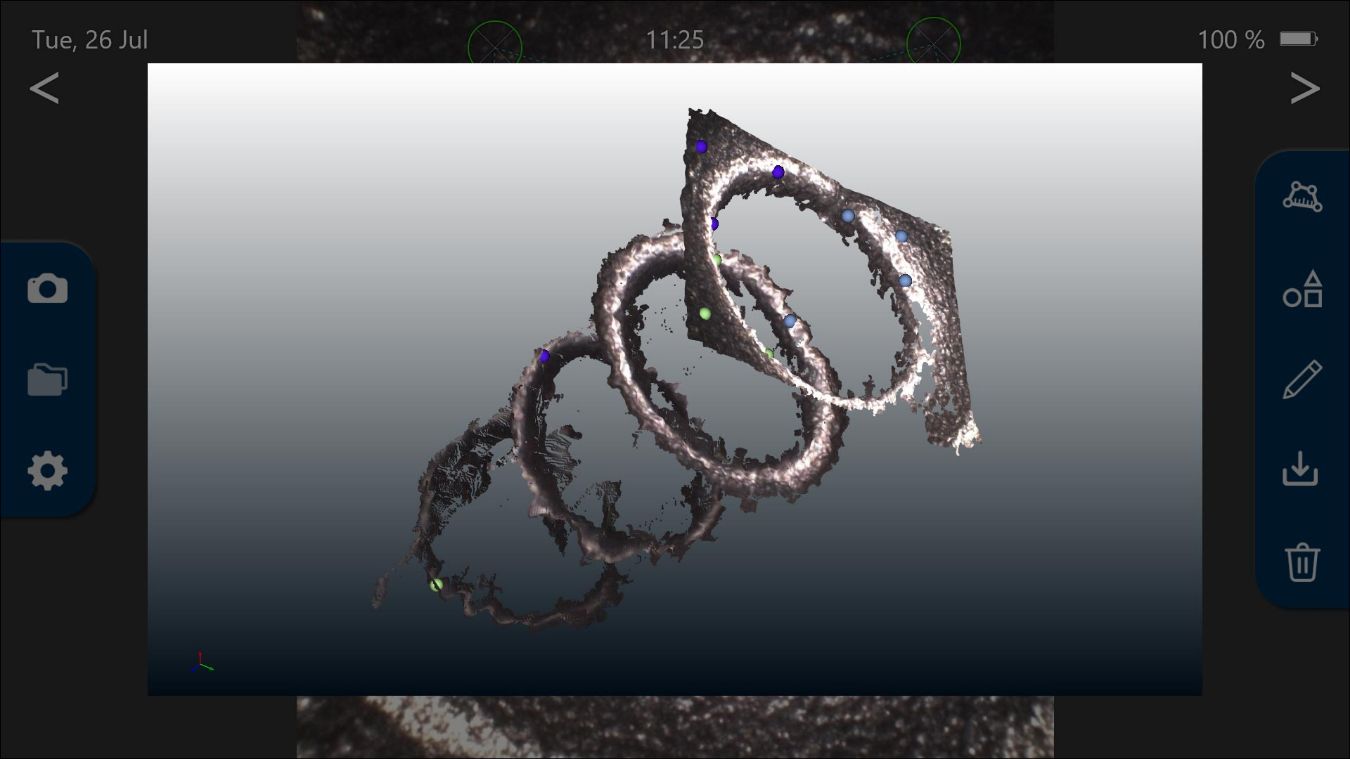

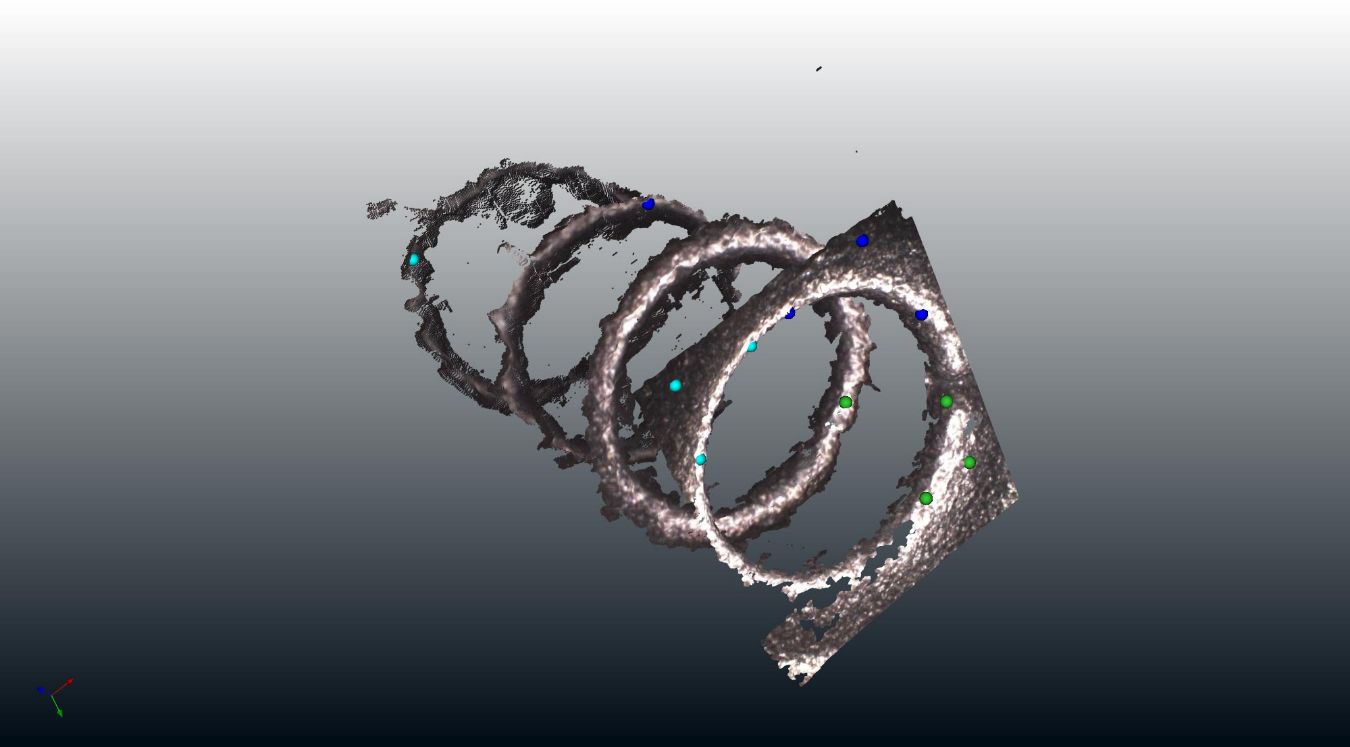

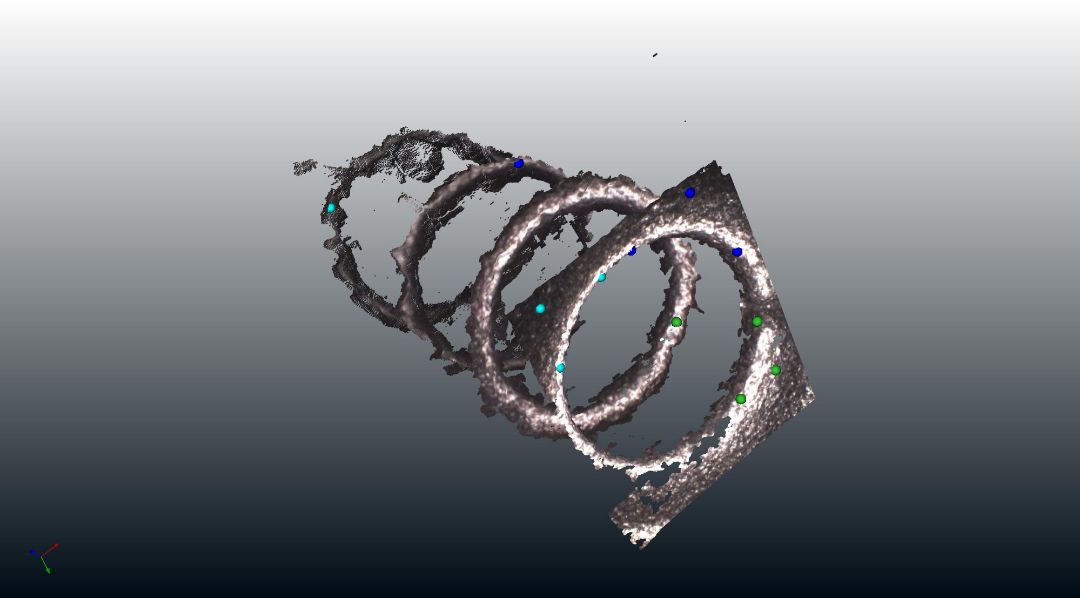

- 3D Point Cloud Generation: The 3D point cloud is a collection of data points representing the inspected surface's three-dimensional geometry. This method allows for a comprehensive analysis of the surface, including volume calculations, surface reconstruction, and feature extraction.

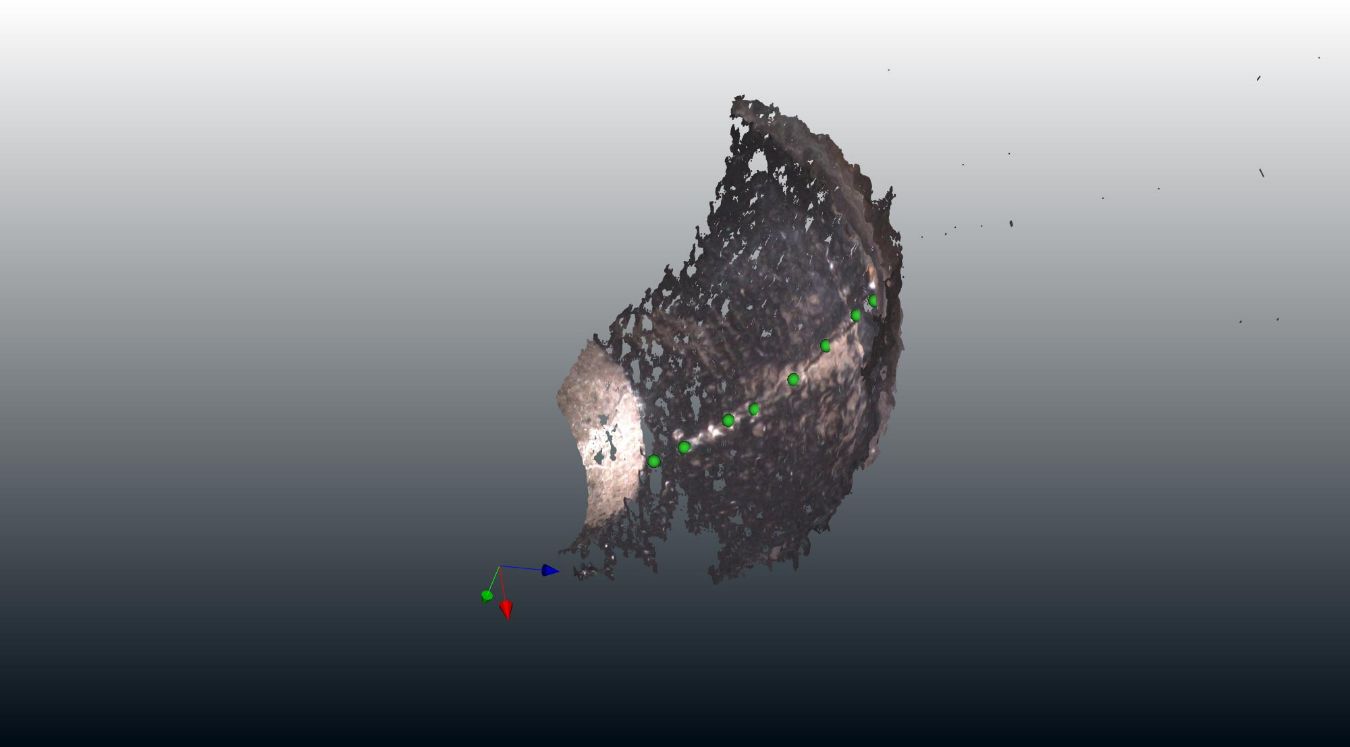

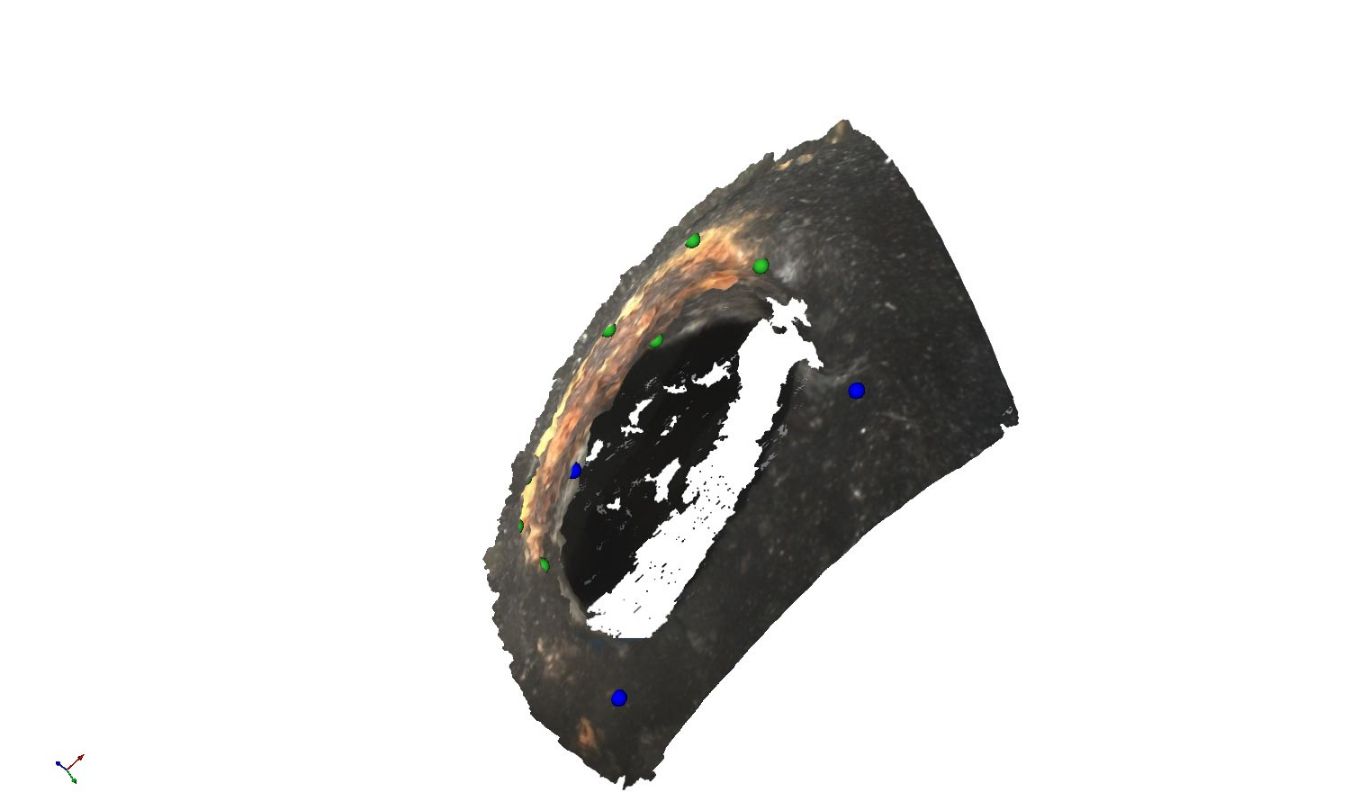

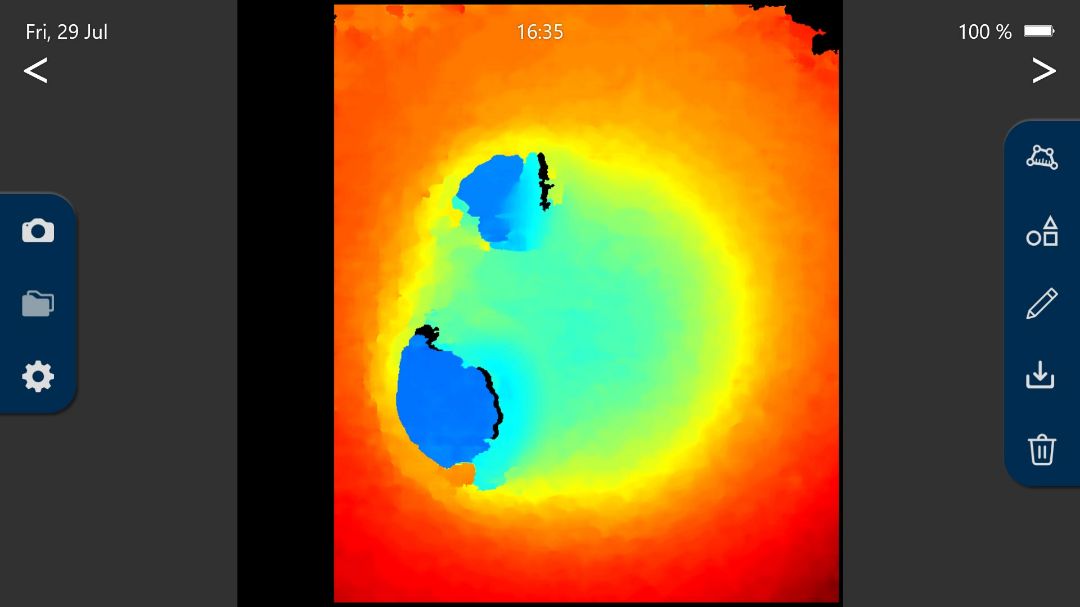

- Colored Depth Map: The colored depth map visually represents the 3D data captured during the inspection, with different colors indicating variations in depth or height. This representation aids in the quick identification of surface irregularities and defects.

- 360° 3D View of Model in Image: This advanced method provides a complete 360° view of the 3D model, enabling operators to examine the inspected surface from multiple angles and identify defects or irregularities that may not be visible from a single viewpoint.

- Shock proofed rugged industry type Tablet PC, IP65 protection class unit, MIL-STD 461G, MIL-STD 810G military standard, Corning® Gorilla® Glass screen protector, Sunlight Readable Outdoor display with digitizer support, up to 11 hours battery life

- 3D stereo measurement and 3D modeling proprietary PXL+ software technology TM exclusively licensed by 3D.aero GmbH

- 2D/3D measurement methods supported: point-to-point, point-to-line, point-to-plane, multipoint line, 3D point cloud, colored depth map, and 360° 3D view with distinct colors for each layer

- 2 AIT Advanced Image Sensor chips per distal end

- High-power LED Illumination on the tip (6mm X PRO) with 3 steps control

- 6mm пrob diameter (outer diameter)

- 1.5m - 7.5m working lengths

- 0° or 90° Direction of View (DOV) stereo camera

- 4-way articulation

- ± 90° rotatable display with ±90° rotatable handle

- Waterproof, oils and saline resistant probe and distal end

- -25°C to +46°C system operating temperature

- -25°C to +80°C tip operating temperature (can withstand up to 140°C for less than 5 minutes)

- Handle material: PA1102, excellent resistance to chemicals, especially hydrocarbons,

- aldehydes, ketones, mineral bases and salts, alcohols, fuels, detergents and oils/greases

- PA1102 is made from renewable raw materials

- Video interface: 8 PIN (for iCapture PRO), HDMI PRO with monitor/touch display, HDMI ZOOM with monitor/touch display

- Wi-Fi remote access

- Industrial grade storage and transportation case

4-Way Articulating 3D Stereo Measurement Borescope Camera

- 4-way articulating video borescope for complete 360-degree field coverage in all of your borescope and videoscope applications

- Articulation mechanism with true Tactile Feel

- Chip in the Tip Advanced Optics & Imaging Technology

- Cold and brilliant fiberoptic or LED in the tip support IT Concepts new and innovative FOLED illumination technology

Visual Inspection 3D Stereo Measurement Solutions in Practice

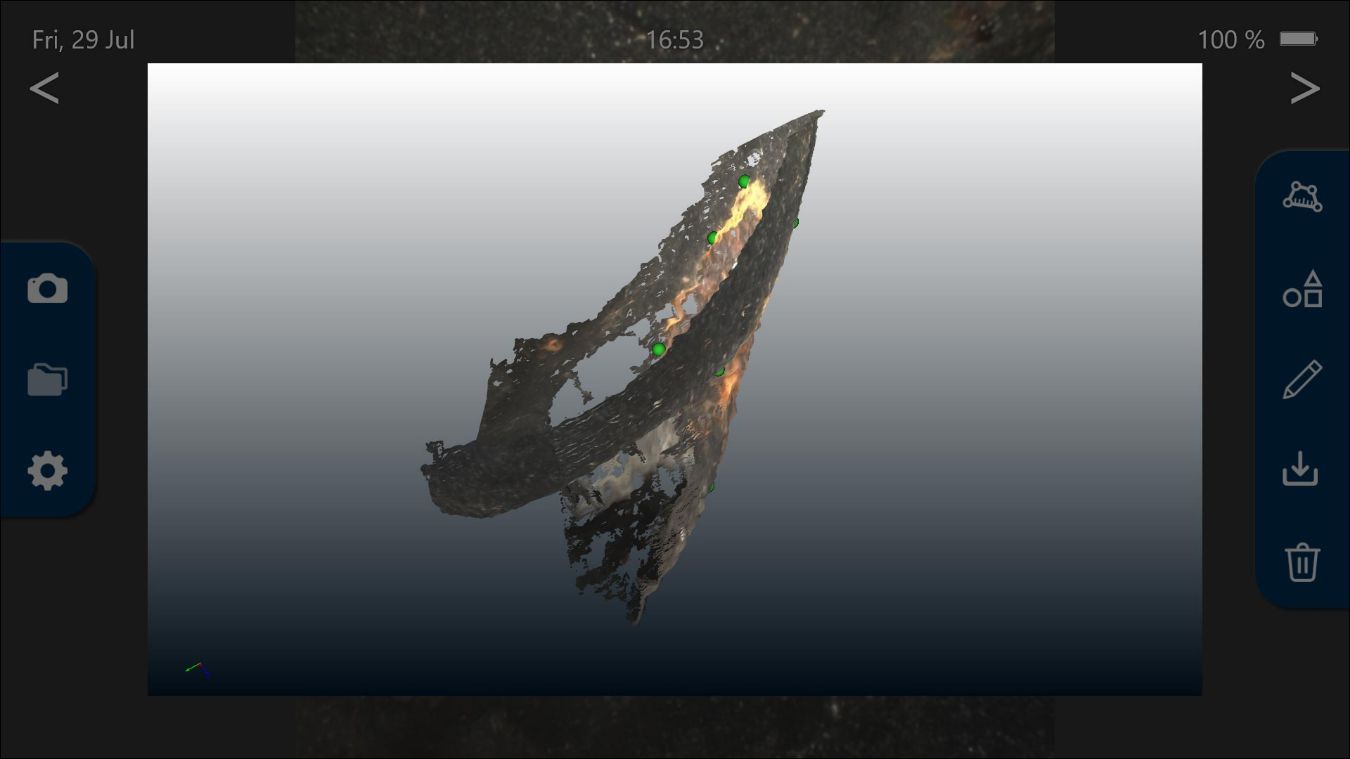

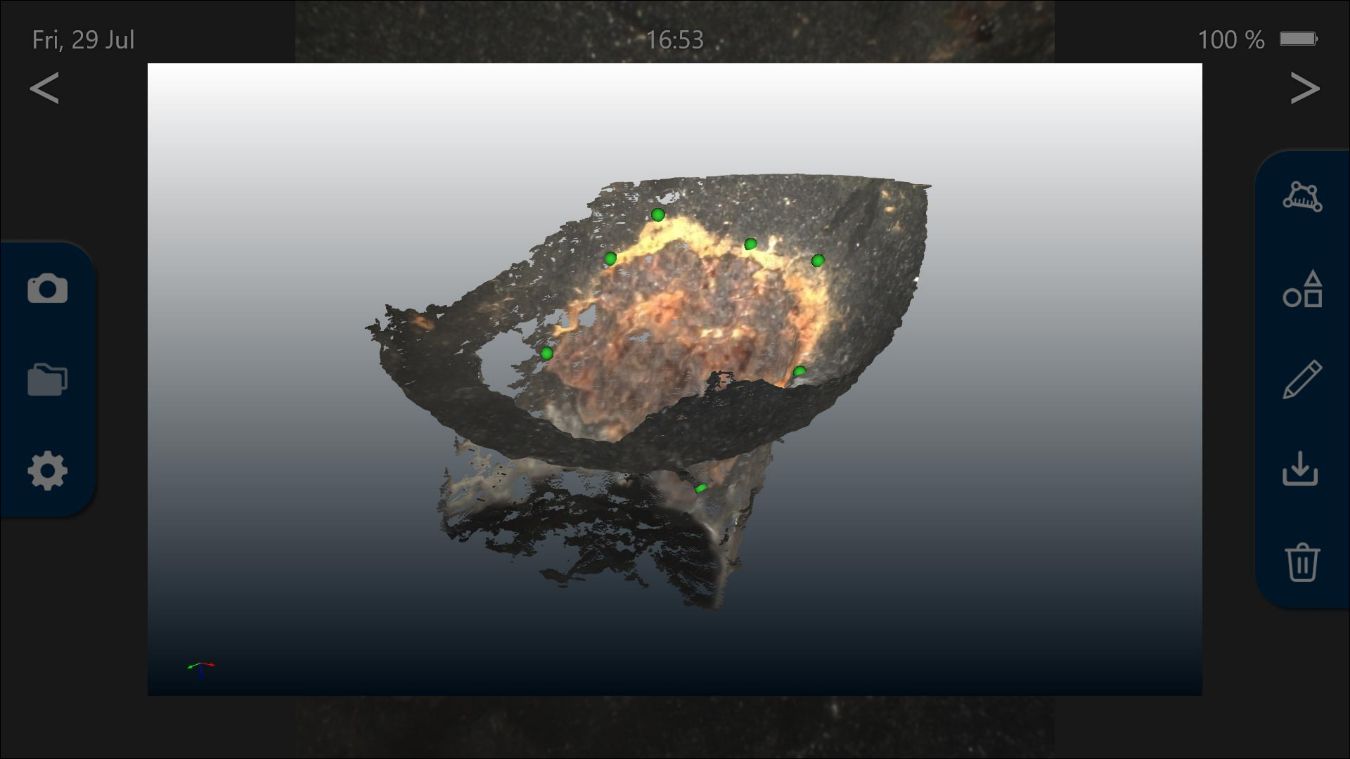

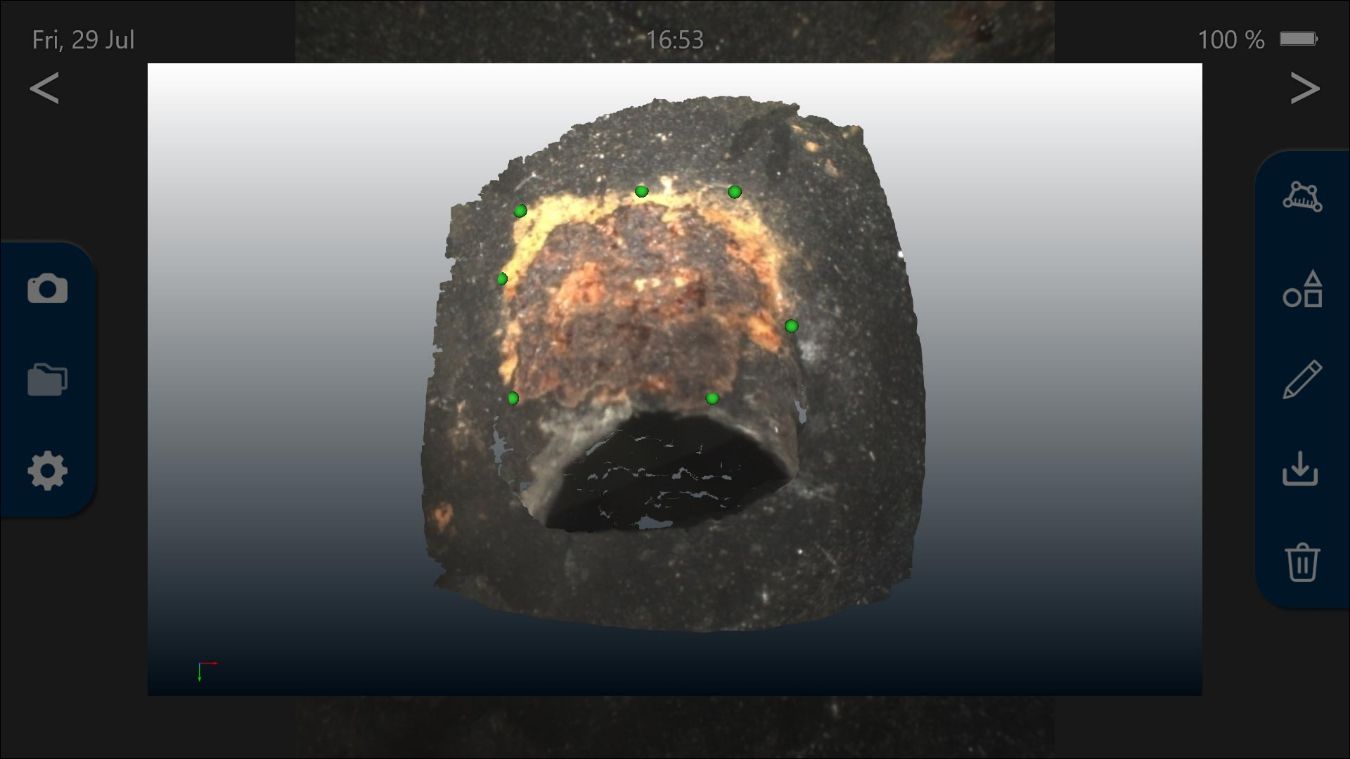

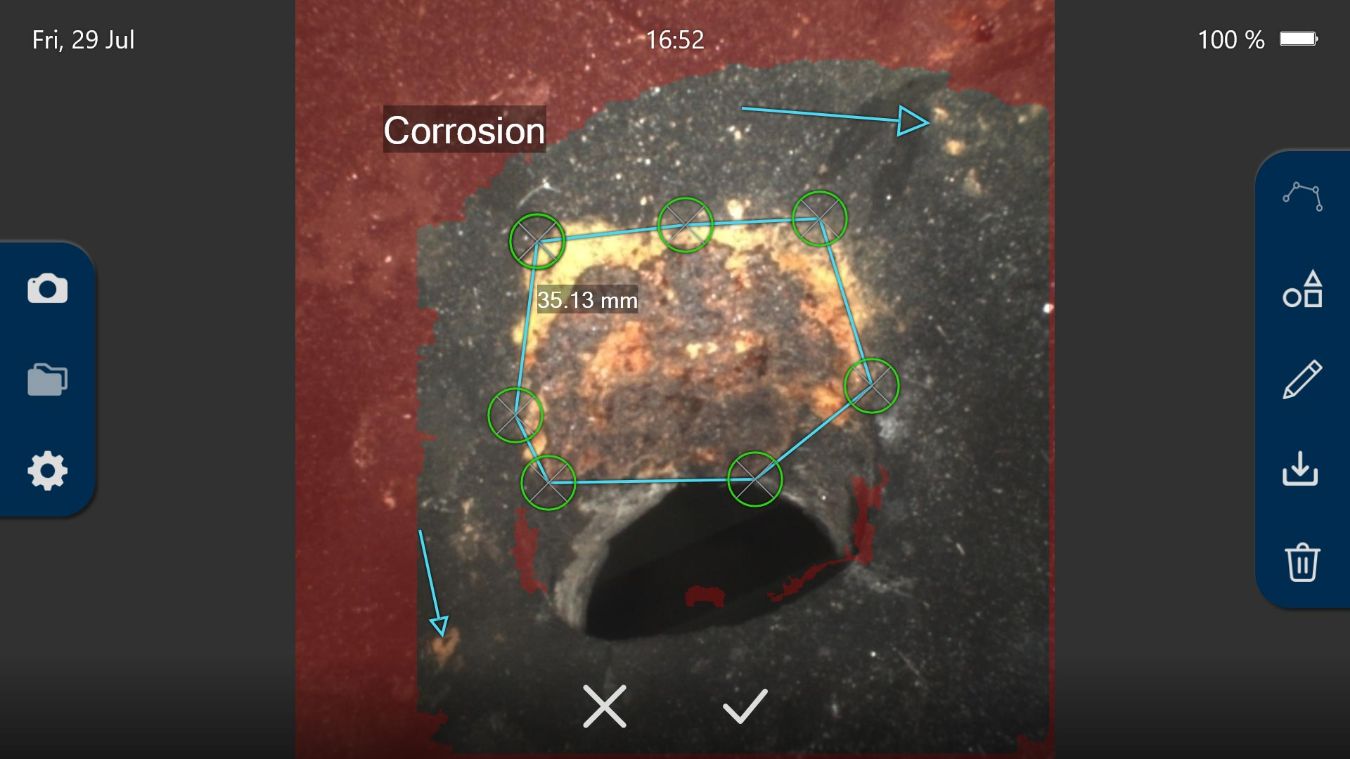

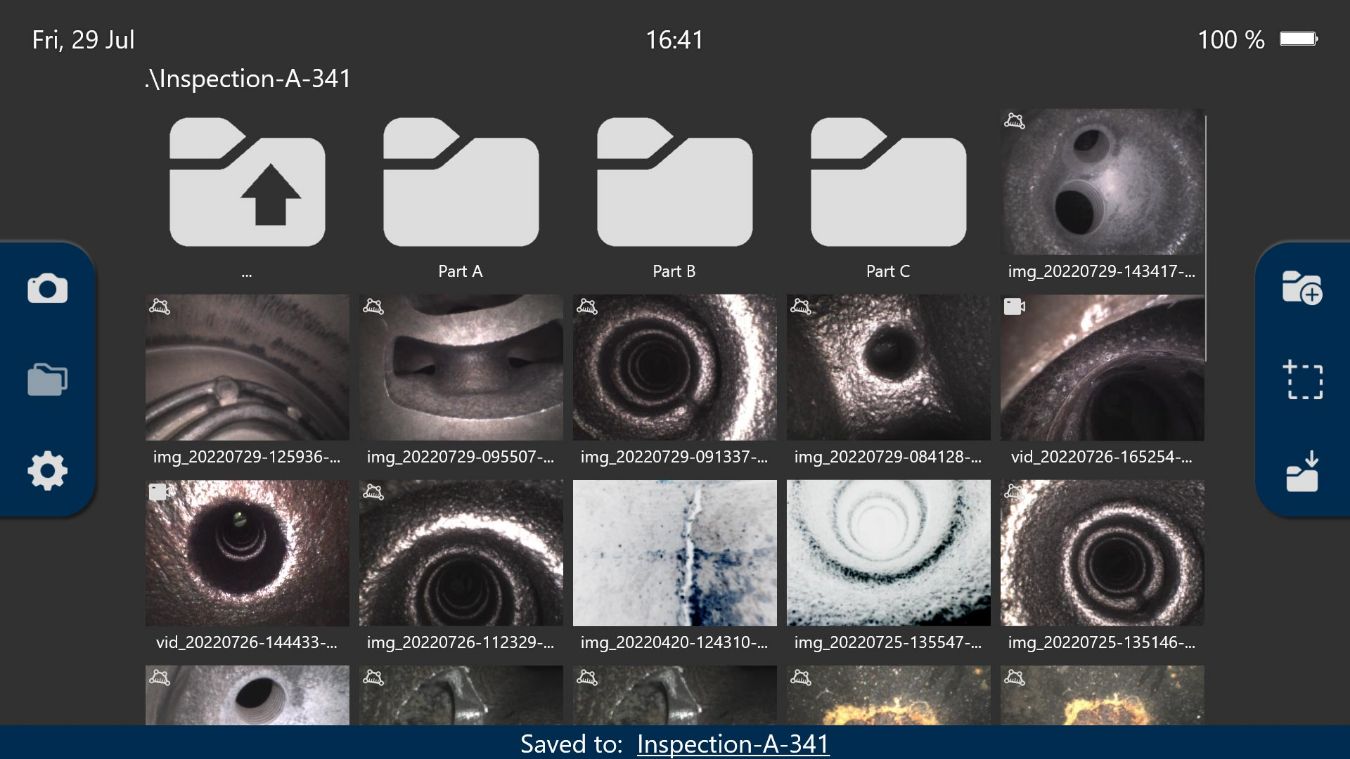

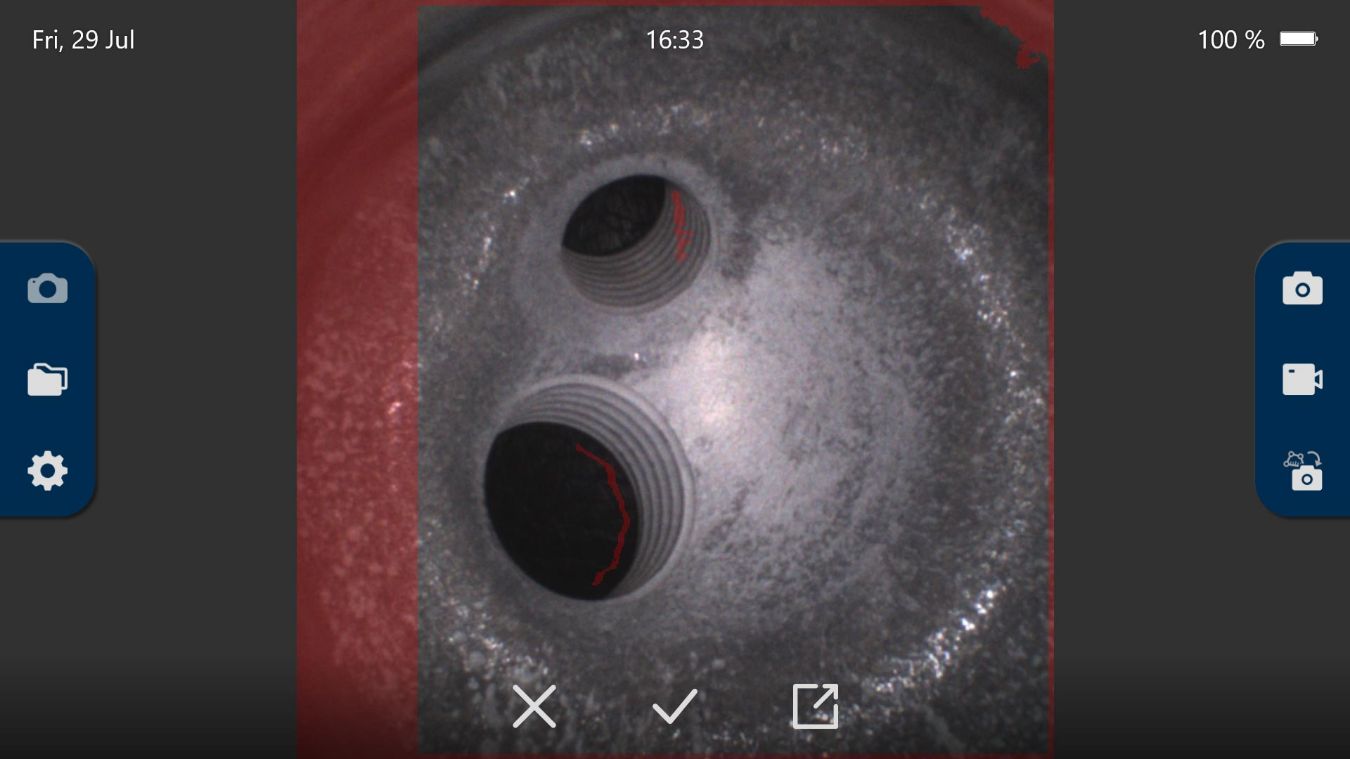

3D Stereo Measurement iX3D Video Borescope Images

Mobile 3D Stereo Inspection

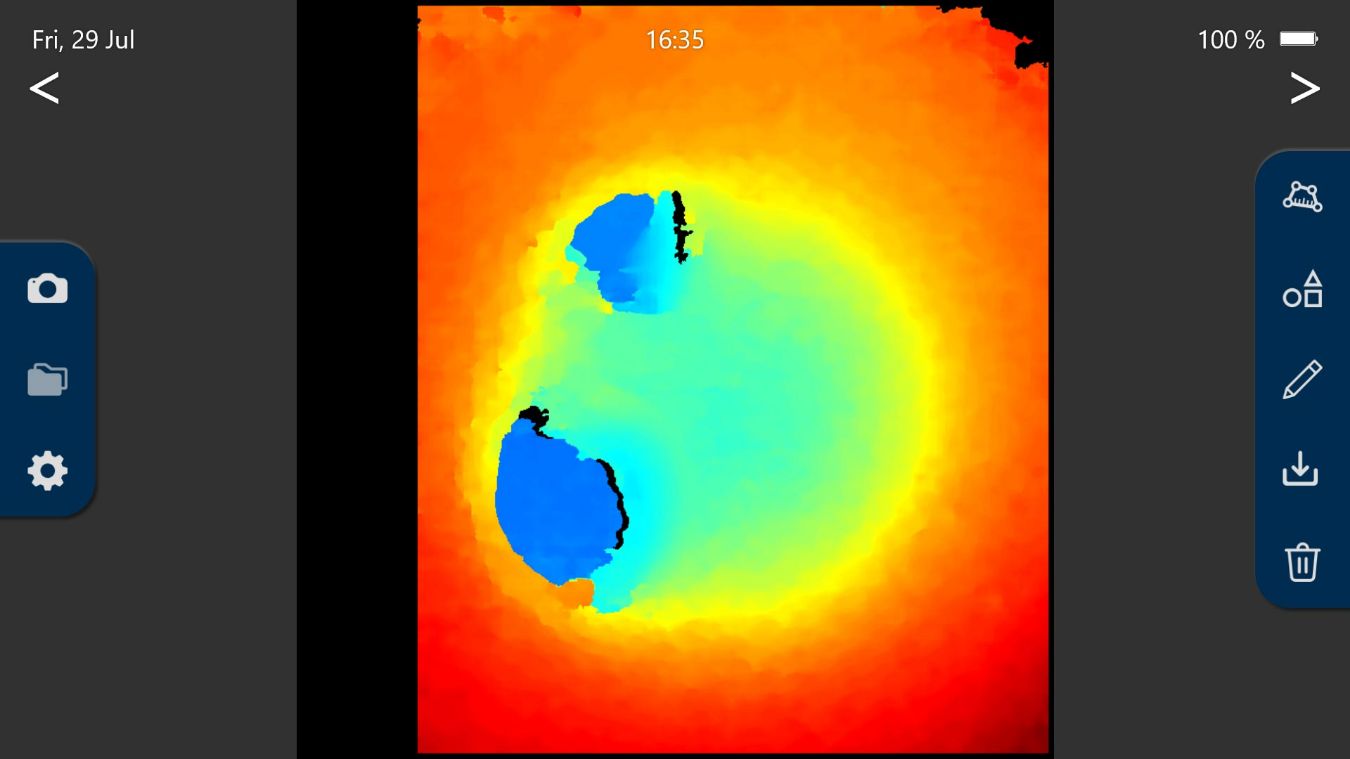

Colored Depth Map

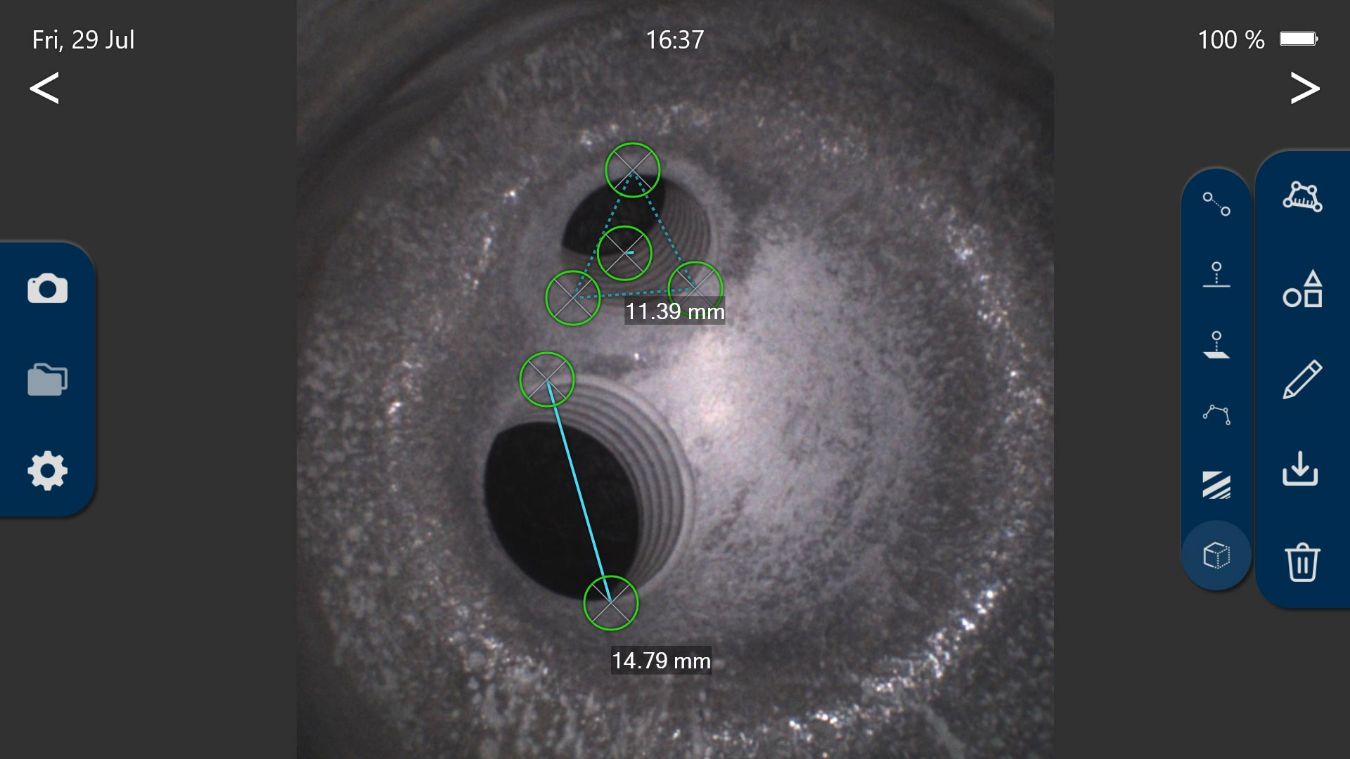

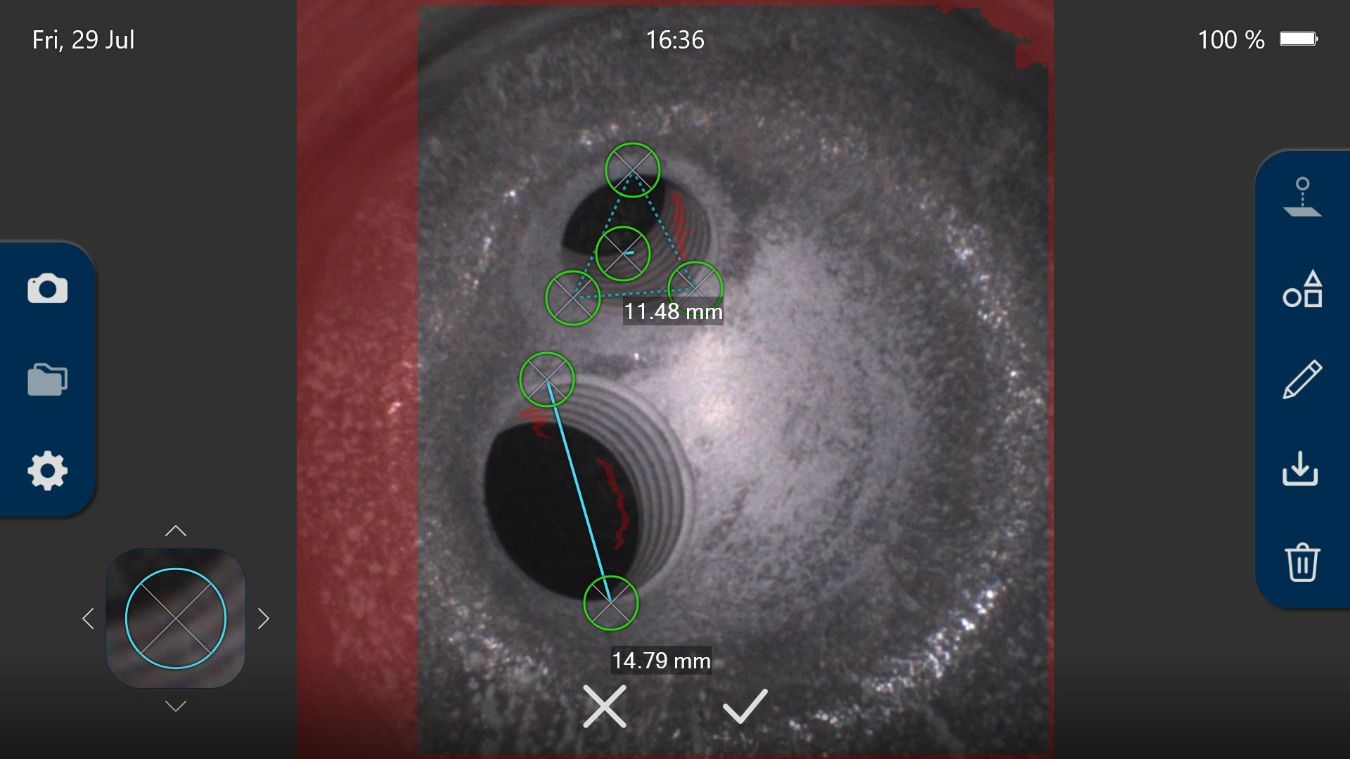

Multipoint Line Measurement

Point-to-Point, Point-to-Plane Measurement

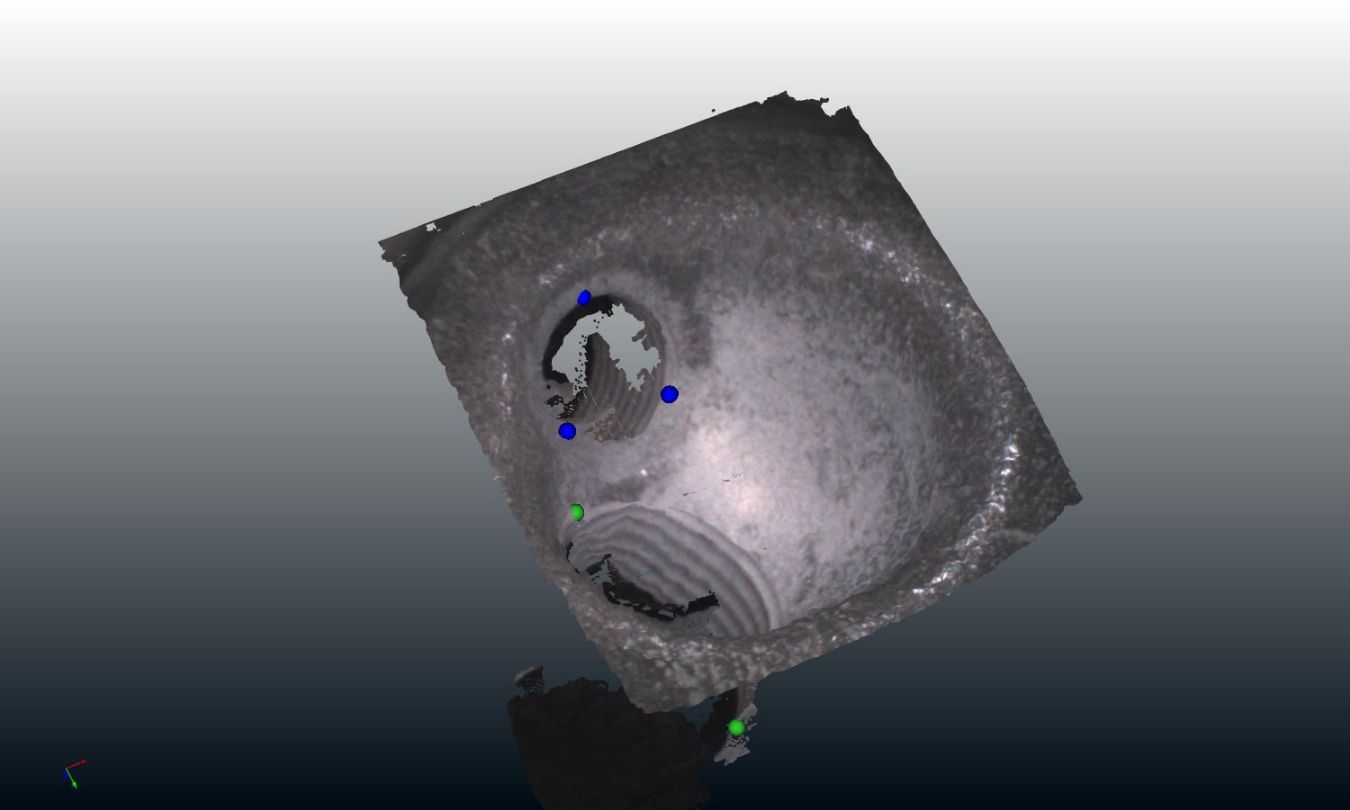

360° 3D Model

Videoscopes, Borescopes, Flexible Fiberscopes, Rigid Borescopes, Borescope Accessories, and Fiber Image Bundles

- Explosion Proof Borescopes

- Small (2mm) Diameter Borescopes

- Working Channel (WC) Borescopes with Tools

- Ultraviolet (UV) Illumination Borescopes

- Infrared (IR) Illumination Borescopes

- Blue Light Borescopes

- Wireless/Wi-Fi Borescopes

- Red Line Borescopes

- Interchangeable Probes Borescopes

- Interchangeable Scopes Borescopes

- Interchangeable Lens Borescopes

- Dual View Borescopes

- Smart Focus Borescopes

- Dual Focus (Near to Infinity) Borescopes

- Regular and Stereo/3D Probe Measurement Borescopes

- Fiber Optic Image Bundles

- Mobile, Portable, Stationary, Combinable & Expandable, Compact & Modular Borescopes, Videoscopes & Fiberscopes

ALL PRODUCTS

Fiber Optic Image Bundle

Bundle Diameter:0.38 - 1.4mm

Length: 0.54 - 3m

Fiberscope and Borescope Accessoties and Parts

Light Sources, Borescope & Fiberscope Cameras, Side View Tips, Tip Adapters, Imaging Hubs, Storage and Transportation Cases

All Products

Rigid Borescopes

Probe Diameter: 1.9 -9mm

Probe Length: 0.175 - 7.5m,

up to 10 - 20m (custom configurations)